Unless you re careful step flashing can allow water from the roof to slip behind the gutter and get behind the siding and even the housewrap.

Flashing against existing panel siding.

Since newer installation guidelines do not recommend caulking this joint but instead recommend leaving a small gap and flashing behind the ends of the siding i think it is more prudent to add flashings when it is possible to do so.

But the j cap also creates a consistent line.

Using a metal j flashing between these types of transitions provides a barrier between siding and transitions that protects against water intrusion.

Hold a panel at the correct height and against a window or other obstruction to mark for the horizontal part s of a cutout.

A key part of my approach is using a special piece of flashing at this vulnerable intersection called kickout flashing or kickout diverter.

Install the kickout flashing underneath the first shingle photo 1.

Flashing is a strip of metal usually aluminum about 8 inches long and bent at 90 degrees with each side at least 5 inches wide.

If the shingle already has flashing on it the kickout flashing has to slip beneath it and you ll have to loosen or remove siding to do this.

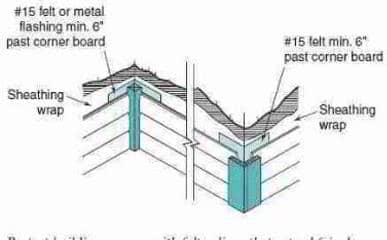

On a wall to be covered with wood cement board vinyl or metal.

Again allow for a 1 4 inch gap.

Cut 1 4 inch above the flashing or window.

Begin at either end of the wall and set the level middle section of the z flashing onto the top edge of the siding panel with the wider flange upward and against the wall framing.

It is always recommended to install step flashing behind stucco dryvit wood panel lap siding vinyl siding cedar shingle siding etc.

Flush the end of the flashing length with the wall corner and secure the flashing to the framing with an 8d nail at each wall stud.

In certain instances flashing may need to be installed on the exterior of siding.